Fixed Wing Aviation Maintenance

95 %

REDUCTION

REDUCTION

DAMAGED MATERIAL

100 %

INCREASE

INCREASE

CAPACITY IN CONTAINER

90 %

REDUCTION

REDUCTION

SETUP TIME

25 %

IMPROVEMENT

IMPROVEMENT

EFFICIENCY FOR MAINTENANCE

PLAN

Identify scope of DET

Identify maintenance need

Create load plans

Coordinate transportation

Establish timeline

Identify maintenance need

Create load plans

Coordinate transportation

Establish timeline

PREPARE

Receive spare parts and tools

Pack and stage cages for transport

Load cages on transportation assets

Transport to DET location

Receive and inventory

Set up identically to home station

Pack and stage cages for transport

Load cages on transportation assets

Transport to DET location

Receive and inventory

Set up identically to home station

EXECUTE

Maintain standard operating procedures

Move equipment to aircraft

Lock cages to secore quipment

Move equipment to aircraft

Lock cages to secore quipment

RETROGRADE

Load and lock cages for return transport

Receive and inventory

Distribute to appropriate personnel

Reconstitute based on requirements

Resume training and operations

Receive and inventory

Distribute to appropriate personnel

Reconstitute based on requirements

Resume training and operations

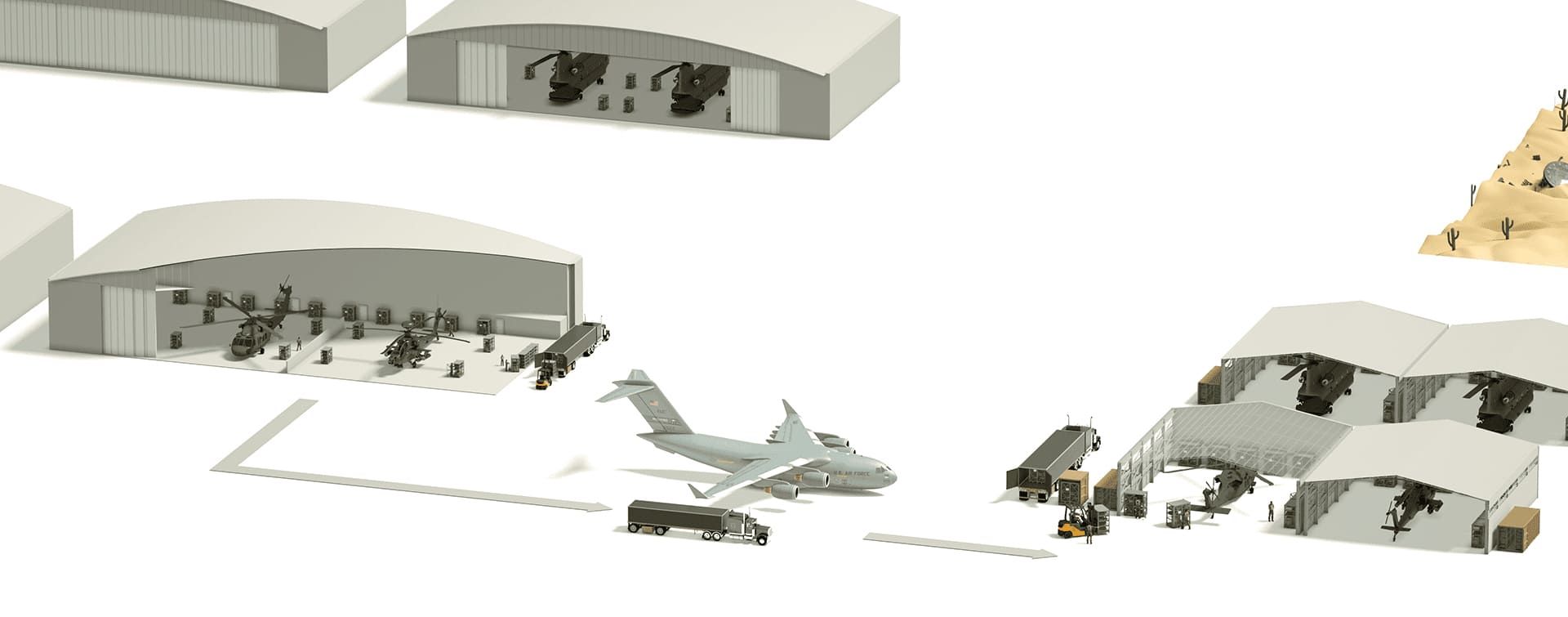

IMPROVE EFFICIENCY IN

MAINTENANCE OPERATIONS

Organizing and storing equipment in SHARKCAGES brings many benefits, including increased safety for both personnel and equipment. In addition, storing equipment and parts based on maintenance phase increases efficiency, while the lockable cages reduce pilferage. The added possibility of deploying with the cage makes the SHARKCAGES an ideal solution for all branches of the military.

Having the parts removed from the phase aircraft and directly into SHARKCAGEs saves one work hour per day, per operator.

Having tool boxes readily available for work within 15ft of the work effort saves a half work hour per day, per operator.

ORGANIZE BY MAINTENANCE PHASE

Optimize aircraft maintenance sequence by organizing parts and equipment according to the order in which the aircrafts need maintenance.

MOVE CAGE TO AIRCRAFT

Move the cage containing the neccessary parts or tools directly to the aircraft.

SECURITY

All SHARKCAGES are lockable with standard issue padlocks. In addition, you can add covers that limit visibility of the contents and offer protection from the environment.

LEAN PROCESS IMPROVEMENT

Increase efficiency through reduced man hours, logistics footprint, and time.

TRANSITION SEAMLESSLY TO

DETATCHMENT AND DEPLOYMENT

When it’s time to detach or deploy, the Sharkcages enable more efficient packing. Staging the equipment in the lockable cages increases transition speed. On the receiving end, inventory and setup time is reduced, while mirroring the home station configuration

is simple.

PACK MORE EFFICIENTLY

Packing equipment in SHARKCAGES gives you a clear overview of what equipment you have packed and how much transportation capacity you need.

SIMPLIFY STAGING

Organize your packed SHARKCAGES by unit or by trans- portation asset. SHARKCAGES are easily secured, and can be stored outside with covers awaiting transportation.

REDUCE SETUP TIME

When arriving at destination, content is easily identified, and can be placed at the desired location by forklift or pallet jack. No need to unpack cages - content is readily available.

INCREASE ACCOUNTABILITY IN RECEIVING

With equipment organized in SHARKCAGES, you always have a clear overview of your equipment and supplies, while still maintaining a high level of security.

100 %

INCREASED

INCREASED

CAPACITY IN CONTAINER

80 %

REDUCED

REDUCED

TIME FOR PACKING AND LOADING

90 %

REDUCTION

REDUCTION

DAMAGED MATERIAL

90 %

REDUCTION

REDUCTION

SETUP TIME

ADAPT TO ON-SITE INFRASTRUCTURE

No two bases are identical. With SHARKCAGES, you can still operate as you do at your home base. Set up a temporary warehouse in a container, or add covers to the cages.

SECURE HIGH-VALUE ITEMS

Sharing space with other units can sometimes require additional security for high-value items such as expensive tools or parts. All SHARKCAGES are lockable with standard issue padlocks. In addition, you can add covers that limit visibility of the contents, and offer protection from the environment.

MAINTAIN STANDARD OPERATING PROCEDURES ON

DETACHMENT

Utilizing SHARKCAGES in your daily operations will not only bring improvements to your home base operations. When deploying with SHARKCAGES, you can operate as you do at home. Save time and money, while also improving safety.

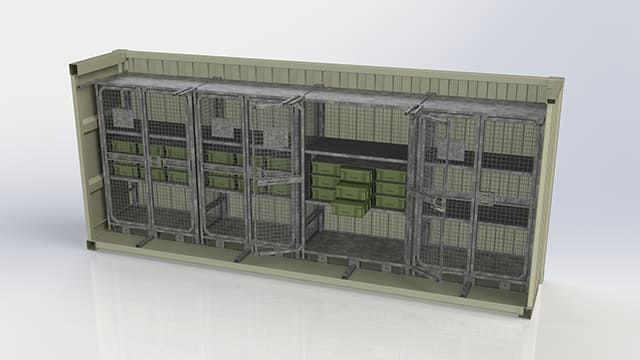

TACTICAL LOCKER MEDIUM

With deep wide shelves and an optional box rack solutions, the cage is perfect for storing anything from small to large items.

20 FT

FLAT RACK

TRICON

463L-AIR

No of lockable compartments

SC-TL-MD-2D-03

70’’ / 41’’ / 79’’ ( W / D / H)

70’’ / 41’’ / 79’’ ( W / D / H)

Weight 890lbs

Capacity 5000lbs

Stackability 15ft

Capacity 5000lbs

Stackability 15ft

3 compartments - 3 levels

Multiple shelf positions

Multiple shelf positions

TACTICAL LOCKER CWL

Transform a standard 20ft container into a mobile warehouse, with the unique blocking and bracing system. Add a box rack (optional) to store small items.

20 FT

No of lockable compartments

SC-TL-WL-2D-03

57’’ / 30’’ / 85’ ( W / D / H)

Weight 475lbs

57’’ / 30’’ / 85’ ( W / D / H)

Weight 475lbs

Capacity 4000lbs

Stackability 15ft

3 levels, multiple shelf positions

Stackability 15ft

3 levels, multiple shelf positions

Add blocking and bracing, one per cage with NSN: 8145-01- 499-0720

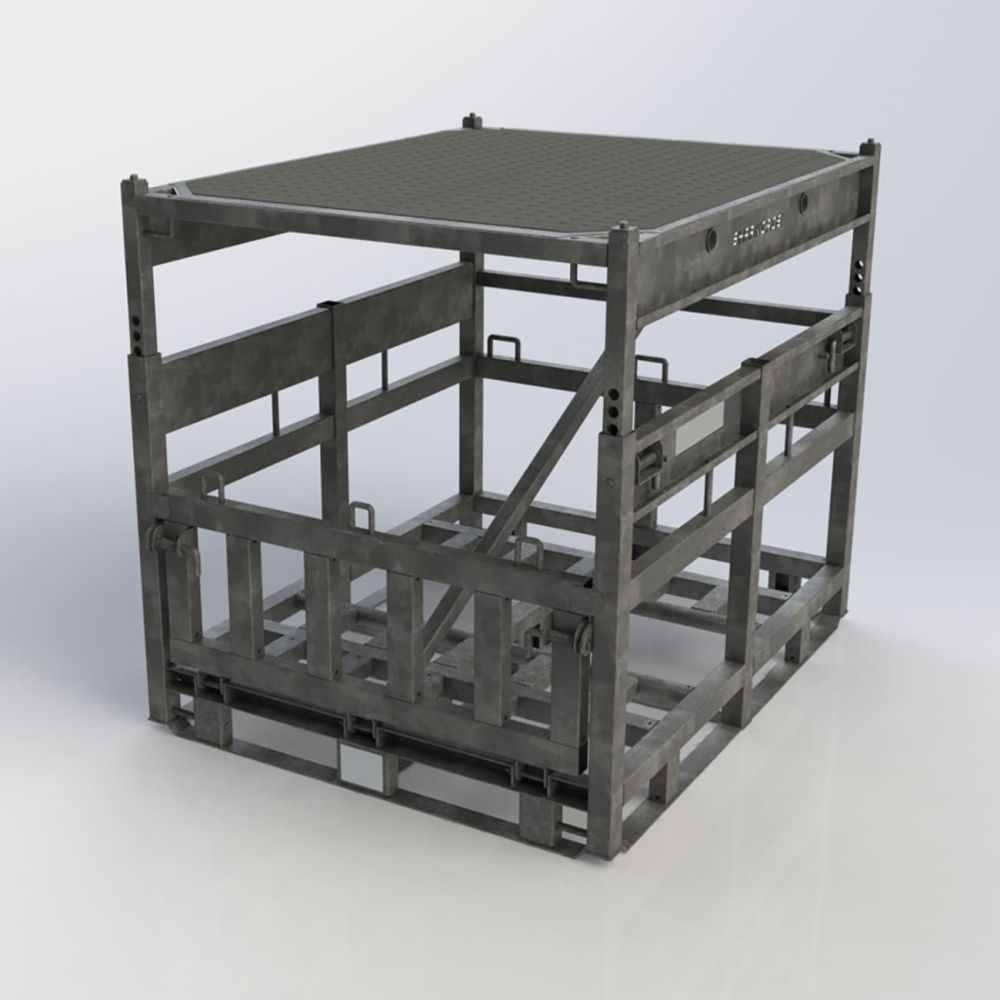

TACTICAL LOCKER i90

TACTICAL LOCKER i90 is designed to work inside ISU-90 containers. The wider door beam makes it possible to open the doors while inside the ISU-90 container.

20 FT

FLAT RACK

463L-AIR

No of lockable compartments

SC-BA-XL-GT-01

84’’ / 52’’ / 43’’ ( W / D / H)

84’’ / 52’’ / 43’’ ( W / D / H)

Weight 660lbs

Capacity 4000lbs

Stackability 15ft

Capacity 4000lbs

Stackability 15ft

1 compartment - removable dividers available (accessory)

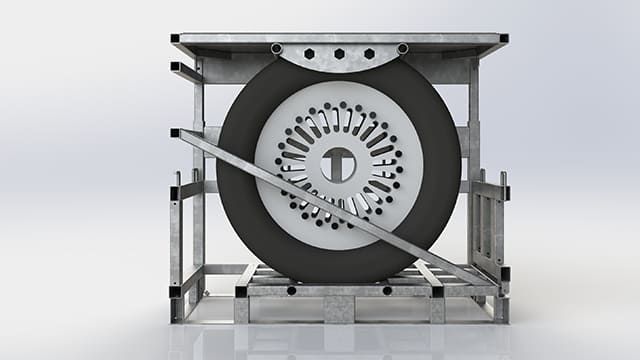

WST III

To securely store and transport two wheels vertically, we designed the Wheel Storage & Transport (WST) III. It can be stacked four high in the warehouse, and it can adapt to a wide range of wheel sizes.

20 FT

FLAT RACK

463L-AIR

SC-CI-LG-4P-02

84’’ / 42’’ / 85’ ( W / D / H)

84’’ / 42’’ / 85’ ( W / D / H)

Weight 960lbs

Capacity 5000lbs

Stackability 15ft

Capacity 5000lbs

Stackability 15ft

4 compartments - 4 levels

Multiple shelf positions

Multiple shelf positions

T-RAX // STACK RACK XXL+

The STACK RACK XXL+ accommodates pallets and boxes that are too large to carry by hand. They are built up or flat packed in minutes. Ideal in an area where permanent pallet racks can not be installed or where there is a need to change layout often. Red and blue color is optional.

20 FT

FLAT RACK

TX-SR-XX-ST-01

115’’ / 44’’ / 56’’ ( W / D / H)

115’’ / 44’’ / 56’’ ( W / D / H)

Weight 330lbs

Capacity 5000lbs

Capacity 5000lbs

Stackability 15ft

1 compartments -1 levels

1 compartments -1 levels

BOX-RACK with workbench

Our BOX-RACKS works as drawers, but you can easily pull the box out and bring it with you. The box racks are without moving parts, which makes them extremely durable in wet or dusty environments. Boxes come with smaller internal divider boxes. Available also for the TACTICAL LOCKER CWL, but without the Work Bench.

For:

TACTICAL LOCKER MEDIUM

PC: BR-WB-04-03-81

Includes 9 ea POB-6 boxes and 3 ea SLIDE-6.

For:

TACTICAL LOCKER CWL

PC: PR-RC-03-03-81

Includes 9 ea POB-6 boxes.

Without Workbench.

SUCCESS STORIES

Several units have already been made fully deployable by implementing SHARKCAGES.

The SHARKCAGE is chosen not only because it is deployable, but because of the benefits the cages add at home station. Lockable cages that can be moved around by pallet jack reduce pilferage and ensure flexibility to meet future demands. Don’t hesitate to contact one of our solution advisors to help you with your logistic challenges!

The SHARKCAGE is chosen not only because it is deployable, but because of the benefits the cages add at home station. Lockable cages that can be moved around by pallet jack reduce pilferage and ensure flexibility to meet future demands. Don’t hesitate to contact one of our solution advisors to help you with your logistic challenges!

F/A-18 Hornet maintenance, Photo by SHARKCAGE Inc.

Chinook maintenance, Photo by SHARKCAGE Inc.

Apache Longbow maintenance, Photo by SHARKCAGE Inc.

Fly-away package for F-35 JSF, Photo by SHARKCAGE Inc.

CONTACT ONE OF OUR OFFICES

United States

EU

Norway

Copyright © 2025 SHARKCAGE Inc